From Robotic Eyes to Full-Stack Embodied Intelligence Solutions

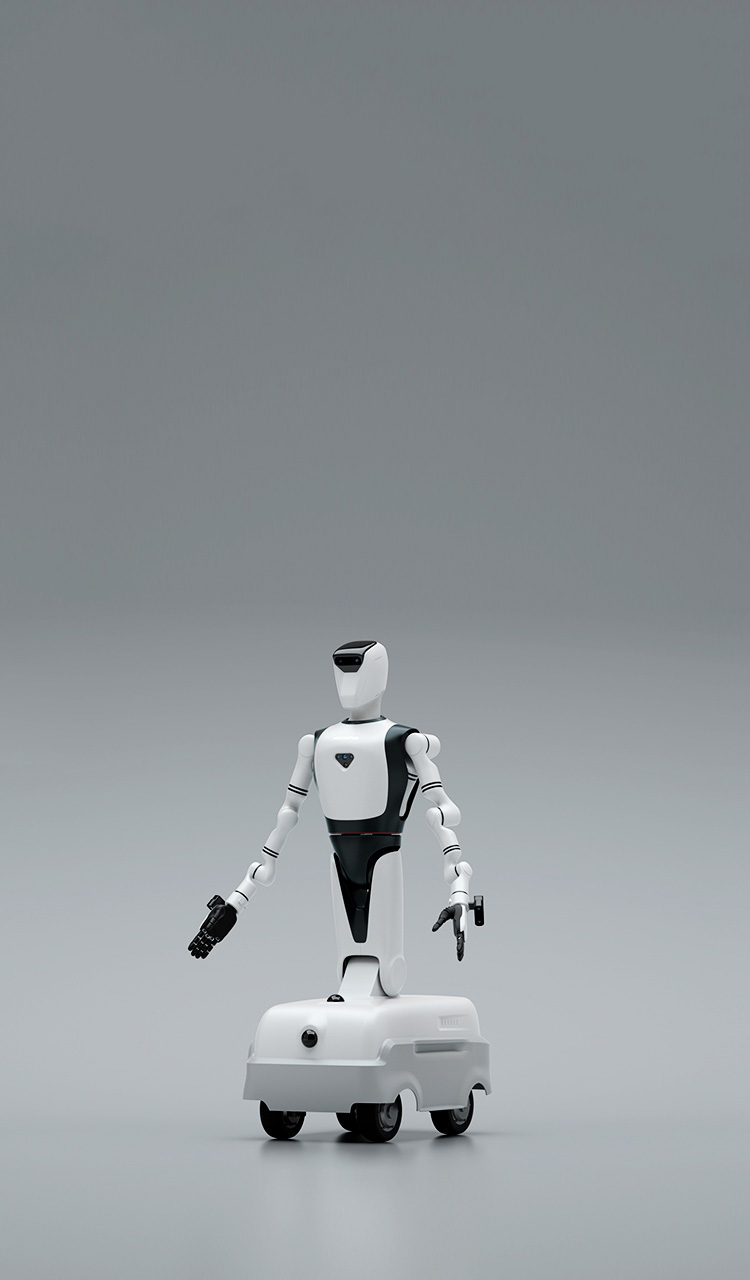

Over the past decade, RoboSense has dedicated itself to robotic “eyes” (perception), ultimately becoming a global leader in the field. Today, RoboSense is combining its deep expertise in physical AI with self-developed hand–eye coordination solutions to build a fully integrated technology loop—from environmental sensing and data acquisition to decision-making, planning, and precise execution—empowering robots with complete operational capabilities.

Active Perception & Decision-Making

AI-Powered Development Acceleration

Ready for Mass Deployment

Hand

Multi-DOF Dexterous Hand

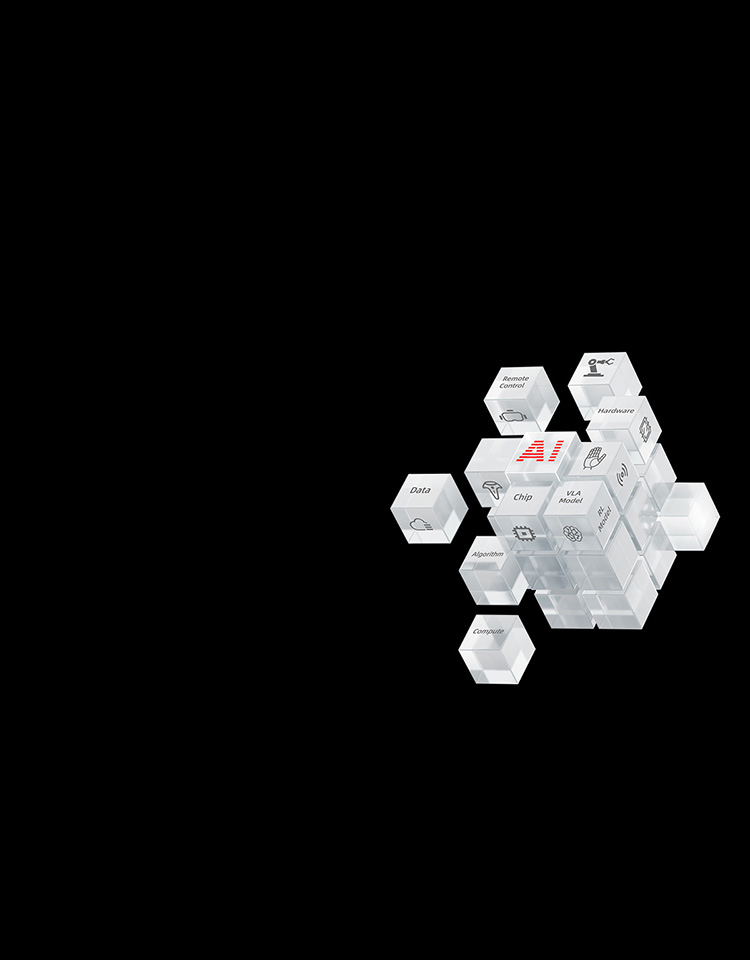

AI Defines Hardware; Hardware Shapes the Chip

-

AI

RoboSense continues to expand its AI research and development, building robust AI infrastructure including supercomputing centers, AI models, and scenario data. The company has also developed large-scale, data closed-loop toolchains, and its self-developed VTLA-3D model enables long-horizon planning capabilities, allowing robots to execute more than ten sequential actions autonomously.

-

Chips

RoboSense has established a comprehensive chip R&D system, covering digital computing chips, optoelectronic chips, MEMS chips, and analog chips, with proven in-house success. Within LiDAR systems, the company has achieved multiple industry-first mass production milestones for self-developed chips, including RISC-V-based data processing SoCs, digital large-area SPAD-SoCs, 2D addressable VCSELs, and 2D MEMS devices.

-

Hardware

Over the past decade, RoboSense has accumulated extensive expertise and talent in hardware system R&D. The company has built substantial technical capabilities across multiple hardware domains, enabling the development of advanced products in areas such as robotic system integration, sensors, controllers, and actuators. RoboSense also operates a CNAS-accredited authoritative laboratory, supporting performance testing and failure analysis for high-precision hardware products across dimensions including environmental, mechanical, EMC, and electrical performance.

-

Mass Production

RoboSense maintains a high-standard automotive-grade quality and safety management system, certified under ISO 26262, ISO 21434, IATF 16949, and ASPICE CL2. The Mars Intelligent Manufacturing Base focuses on smart sensors and robotics, covering a total area of approximately 48,000 m² across multiple factories. With an automation rate of 95%, it is capable of supporting large-scale, high-quality production and delivery of robotic products.

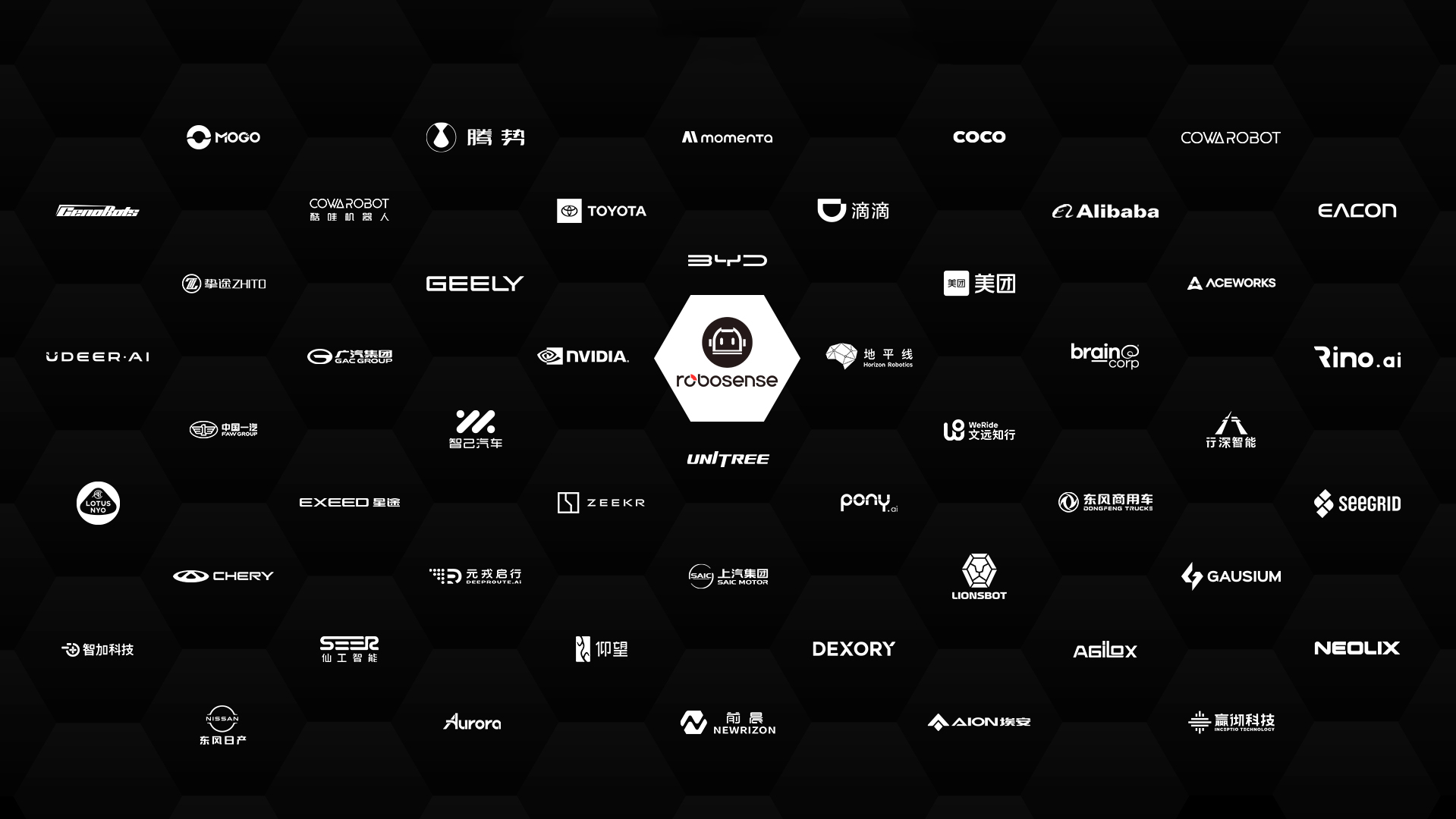

Drive robotics technology into various industries and accelerate the commercial deployment of robots across sectors

A Globally Collaborative Ecosystem